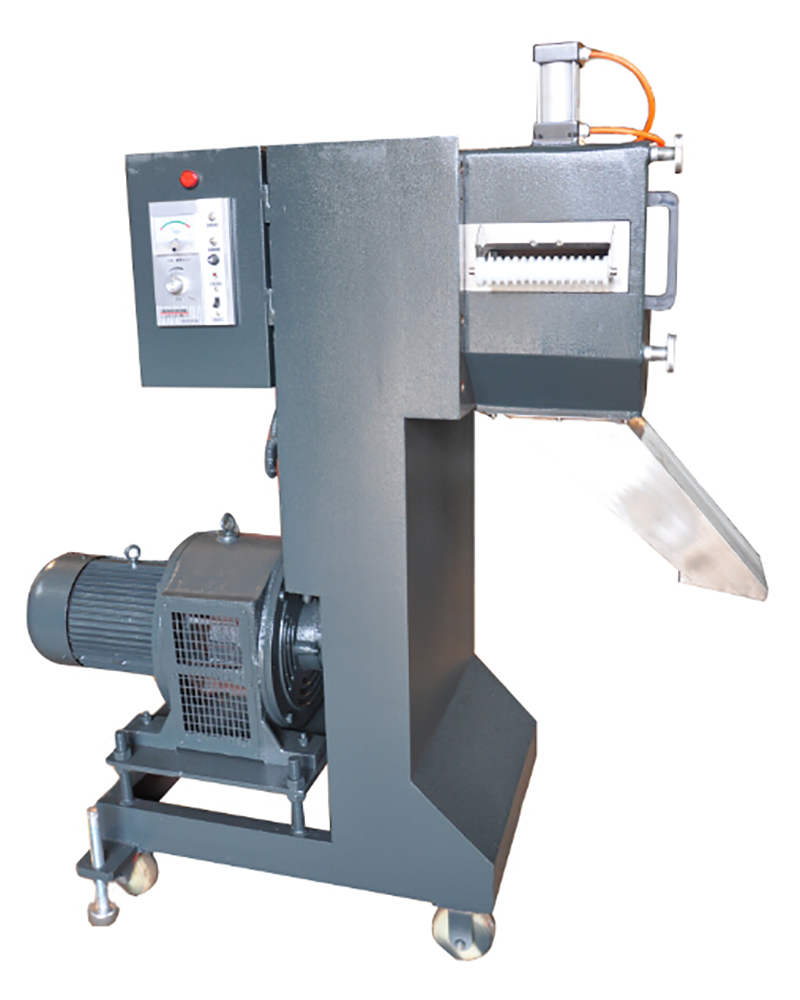

LQ-25 granulator is an experimental granulator. It is mainly used in low productivity working environment such as laboratory, with capacity of 20 kg/h. It is recommended that the number of sliced strips be 1-2. According to the requirement of working environment, it can be made into desktop, horizontal, vertical and other forms.

Product advantages:

1: Cost-effectiveness, cost-effective advantages.

2: Accurate granulation is carried out by strip introduction and strip positioning.

3: Easy to use and control.

4: The introduction of high-precision assembly technology and process manufacturing is the current domestic imported plastic granulator alternative products.

5: Maintenance cost is lower, more suitable for production lines with higher quality requirements and cost-effective, product quality is reliable and stable.

6: All-round humanized safety device, to ensure the automatic shutdown of open cover, to ensure the safety of operators.

7: The main board is inlaid with 304 stainless steel plates to effectively prevent plastic particles from being polluted.

8: The whole enclosed noise reduction device is designed with lower noise and more comfortable working environment.

9: The clearance between hob and fixing cutter of soft material gantry granulator is less than 0.06mm, and the high precision axle core can process materials containing glass fiber less than 50%. The cut plastic particles are more uniform in length, and the appearance of the finished particles is more beautiful and beautiful.

10: It can be equipped with top-level configuration according to different requirements of customers: NSK imported bearings, Siemens motor, various imported frequency converters, imported electrical appliances, etc.

Machine model | Motor power | Speed regulation mode | 切 粒 条 数(根) | Maximum traction speed(m/min) | Pellet size(mm) | Maximum yield(kg/h) | Rotary Cutter Diameter x Length mm | Tooth Number of Rotary Cutter | Cot Diameter x Length mm | Outward Size (mm) (Length, Width, Height) |

LQ-25 | 0.75 | Slip or Frequency Converter | 3 | 72 | φ3×3 | ≤30 | φ90×50 | 14 | φ60×50 | 840×430×1200 |